Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

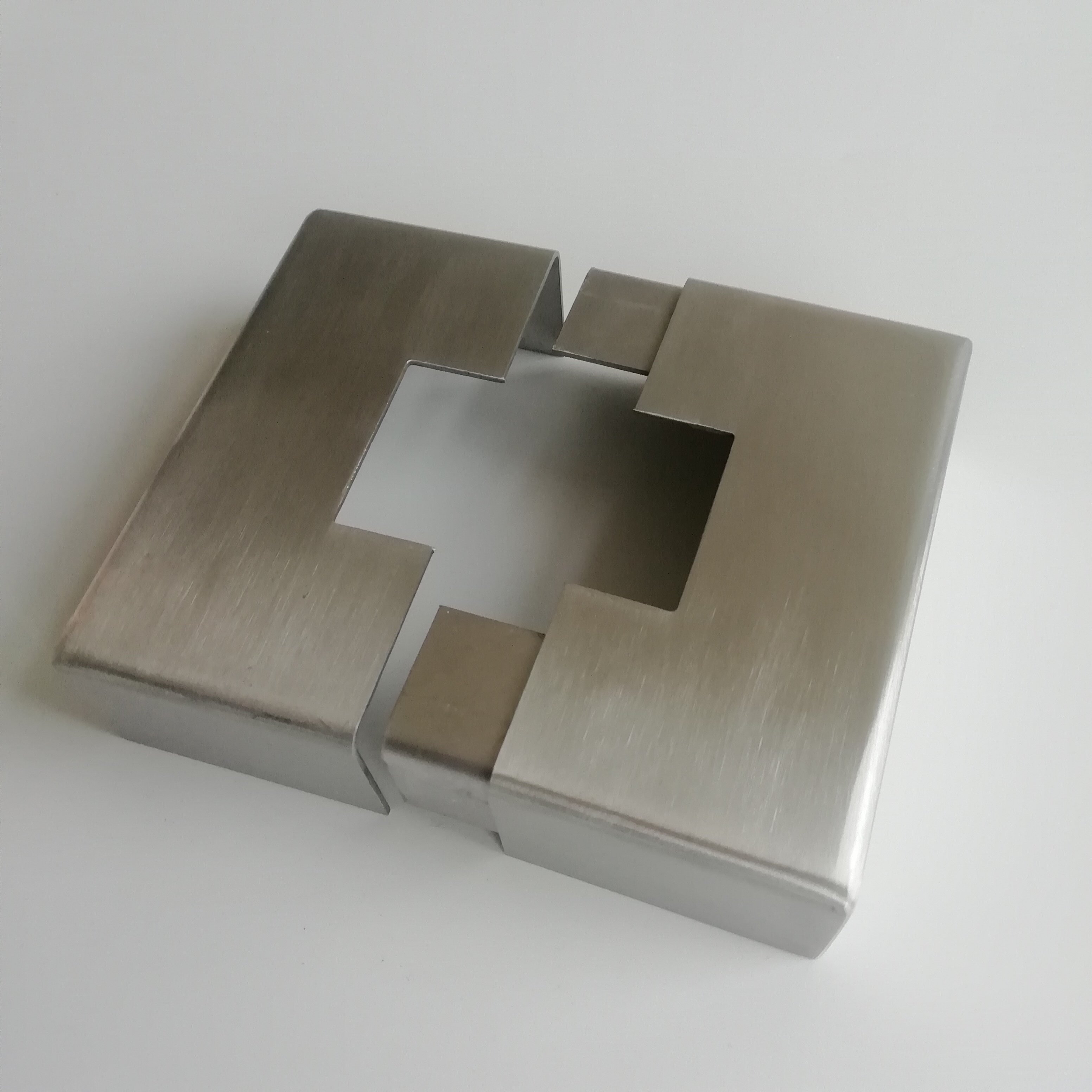

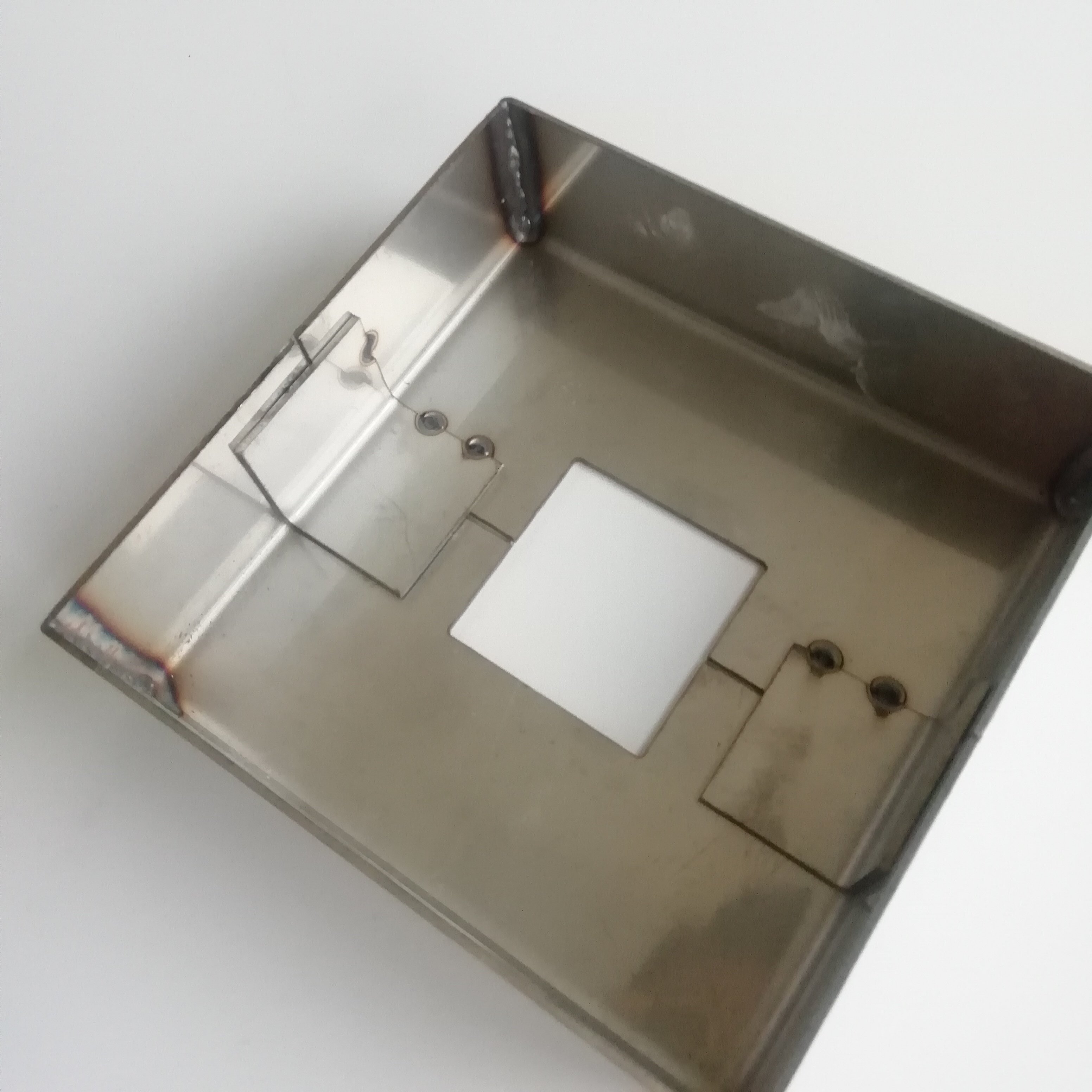

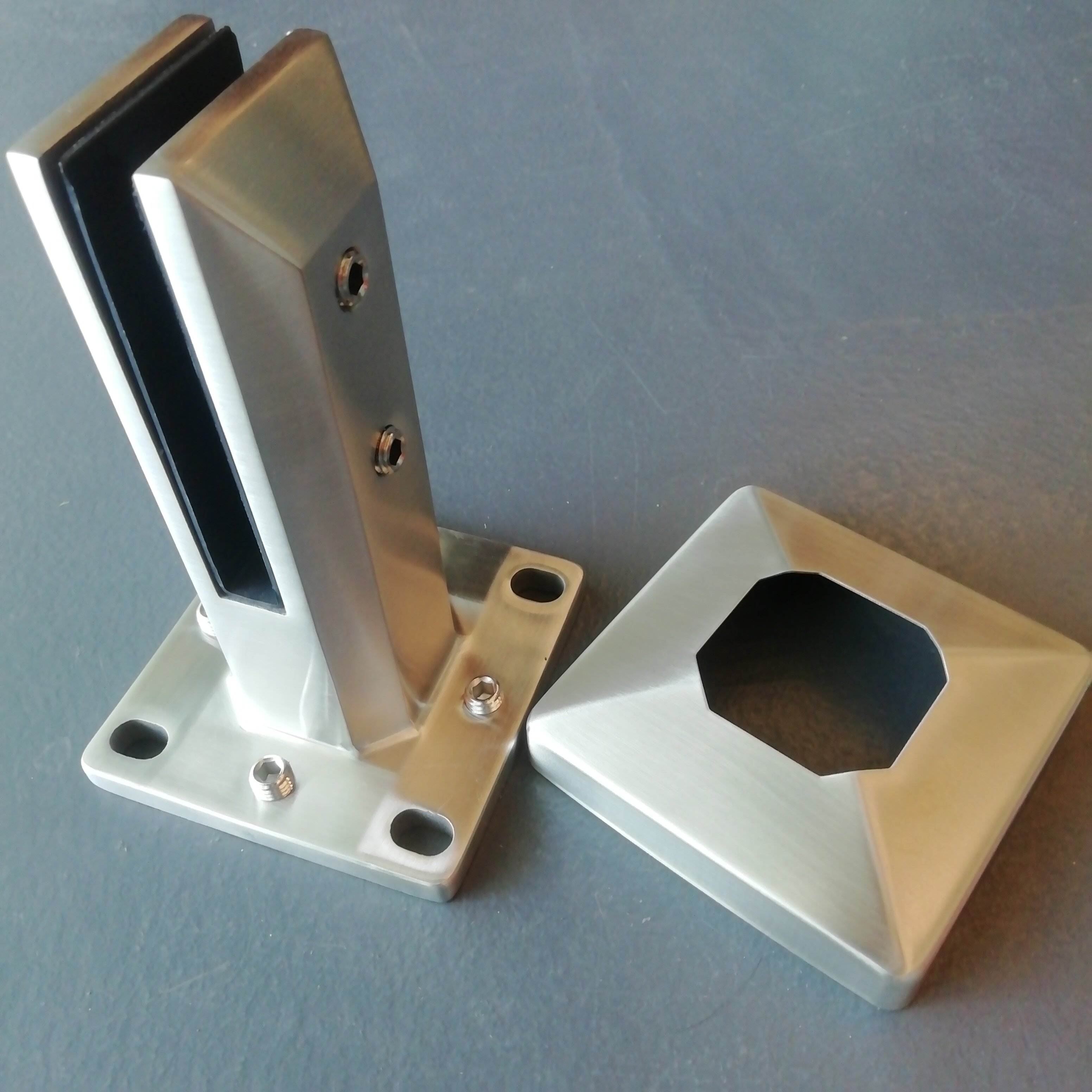

2-split Base Cover

This two-part cover flange is a great way to finish a stainless steel railing or fence installation since it wraps around the base of a post. Fasteners, base plates, flanges, cement, and caulking that don't match the surrounding surface ought to be concealed.

2-split Base Cover

The base of a post is wrapped around by this two-part cover flange, which is a terrific method to complete a stainless steel railing or fence installation. Flanges, base plates, fasteners, cement, and caulking that don't match the surface around them should be hidden.

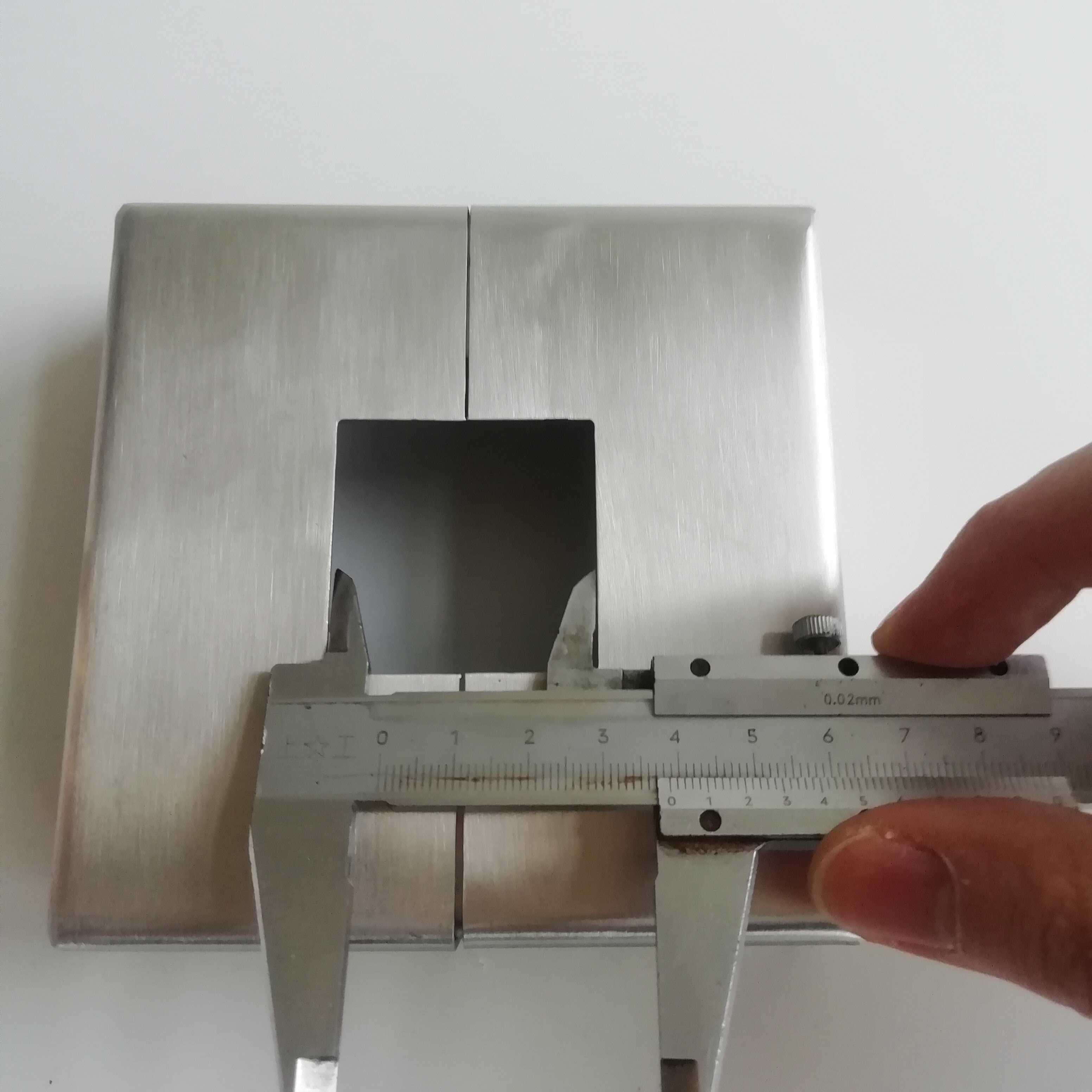

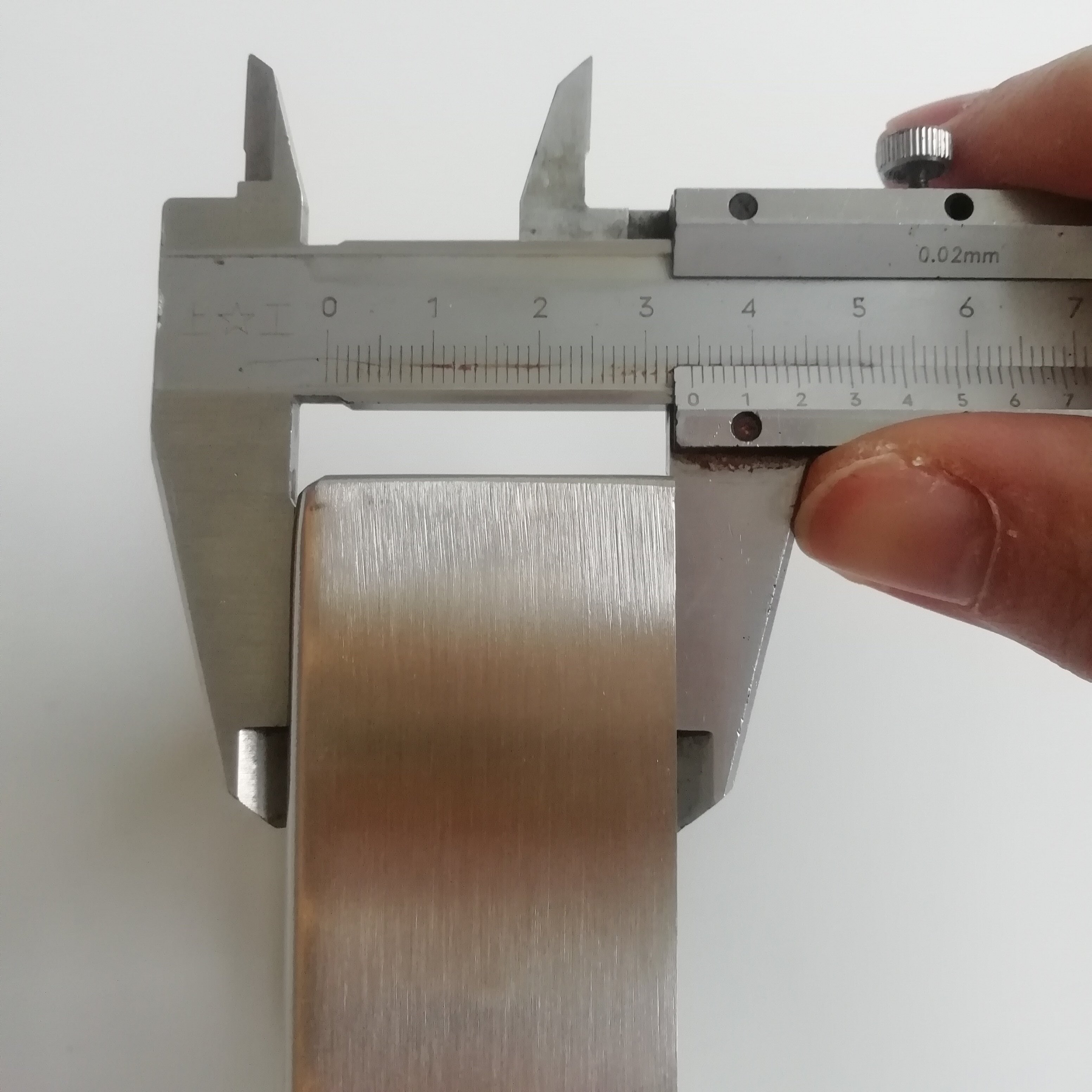

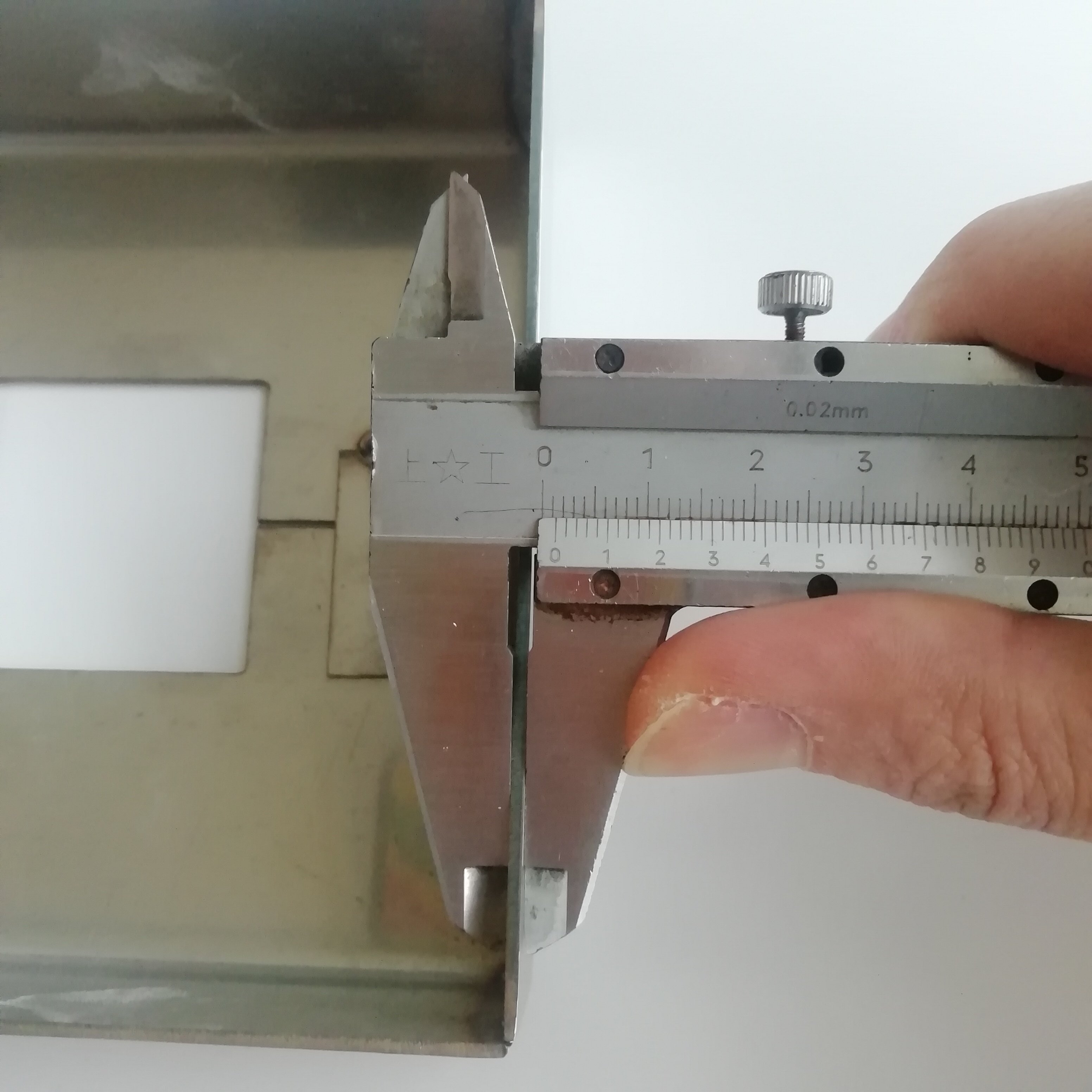

The Standard Specification of 2-split Base Cover

|

Material |

SS201/304/316 |

Surface Finish |

Satin/Mirror/Black/Golden |

|

Size: |

38.1x38.1mm/40x40mm/50x50mm |

MOQ |

10PCs |

The features of 2-split Base Cover

Without disassembling it, retrofit an existing railing!

Even when the task is almost finished, adapt to your client's changing expectations.

Simple to install: We iterated on numerous designs to make installation simple, even when you're in a confined place or posing awkwardly.

The masking panels' top side can be customized to the needs of the customer. The cut, which is a slight matte finish or polish that gives the structure a mirror impression and makes the surface gorgeously shiny, is one of the fundamental surface kinds.

As the maker of the aforementioned base covers, we are able to customize them to the customer's specifications. For instance, the base covers can be polished, sanded, painted, prepped for painting, or have different dimensions and sheet thickness than what the customer anticipates. We can also fuse crooked angles upon request.

The advantages of 2-split Base Cover

Simple Access

Flanges are used in industrial applications because they offer simple access for cleaning, modifying, and inspection—essential functions in any application.

No painting, blasting, or welding

The pipe spools don't need to be welded when using flanges. In contrast to other fixtures and techniques, painting and blasting are also not required.

Easy customization and quick construction

In a workshop, many piping spools may be produced quickly and easily. Additionally, they can change from one material to another, such as stainless steel to copper or brass.